Our tarp solutions protect the wind industry

Tarp solutions that fits the whole wind engine

The wind industry demands high standards – as it should. When wind turbine components are transported, handled, or stored, reliable protection is essential.

Covers must fit precisely, withstand harsh weather, and perform seamlessly within complex logistics.

At Hans Aa, we design and develop customised protection solutions that support the entire value chain – from manufacturing and storage to transport and on-site installation.

We become involved early in the process and work closely with our customers to define requirements. That way, we ensure a perfect fit while also optimising handling, reducing risk, and lowering total cost.

Our ambition is always to deliver solutions that create the greatest possible value for our customers. Every cover is tailored to the shape of the component, the complexity of the project, and the surrounding logistics.

Our engineers and technicians do not think in terms of standard products. They think in terms of smart, purpose-built solutions.

With in-house production facilities in Denmark, Poland, and China, we deliver globally – quickly, efficiently, and always on time.

All sites are ISO-certified, and we continuously invest in state-of-the-art machinery that reduces waste, increases production speed, and keeps our pricing competitive – without compromising on quality.

Wind turbine towers

We create tarpaulin solutions to protect wind turbine towers during on- and offshore transportation.

We produce our tarps to fit the customer-specific towers in various colors, also without PVC, printed with graphics, logo, and text.

We meet all demands and wishes for easy and smooth mounting, handling, storage, and other requirements.

We combine our extensive experience with our flexible and innovative mindset to consistently deliver the best protection solutions.

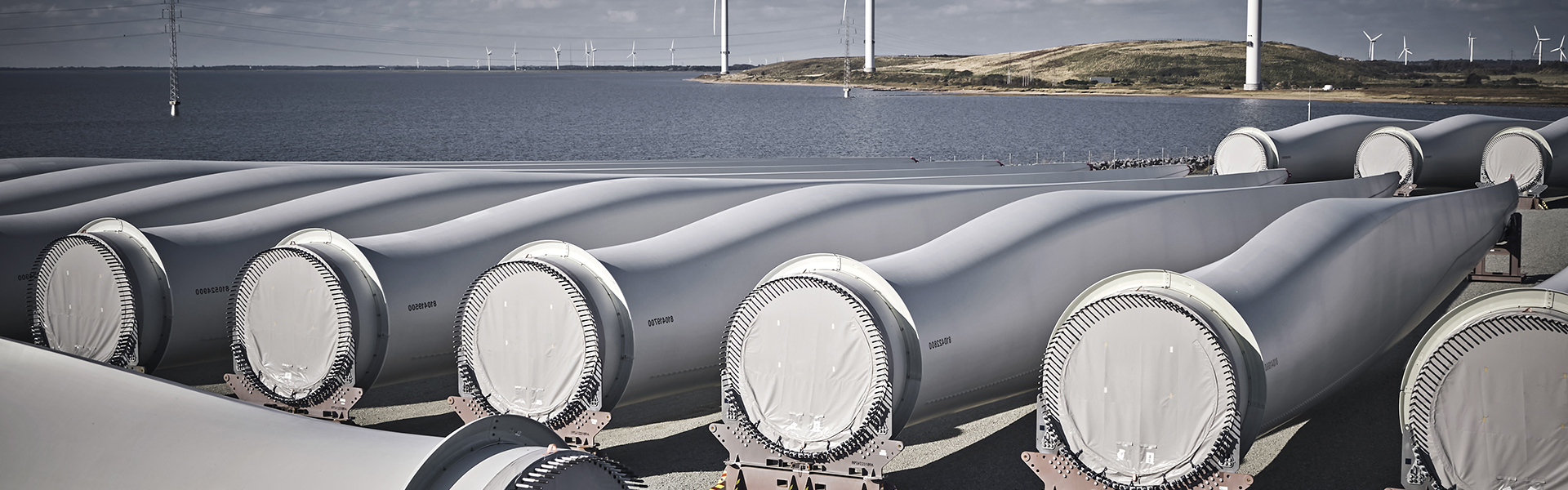

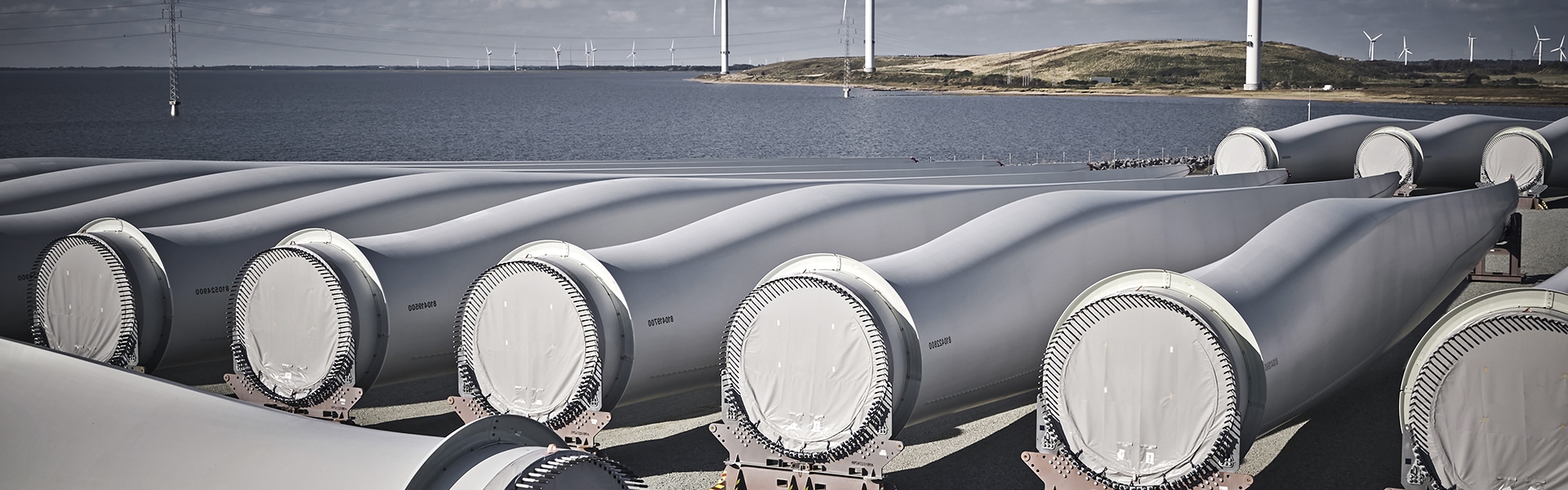

Wind turbine blades

Protection of wind turbine blades is crucial during transportation and storage.

Our experience and knowledge in high-quality protection in tarp ensure that our customers can always expect a cover adjusted for the purpose.

Together with our engineers and craftsmen, we find the right solution for each blade type and make sure that it is delivered on time despite the location.

Wind turbine nacelle

It is essential to cover wind turbine nacelle openings during their transport from the factory, whether their final destination is storage or installation.

Our custom-fitted tarps help ensure that no electronic or other sensitive installations are damaged from dirt or water.

We can create modifications, such as exceptional transport requests, protective layers, and one-person installation.

Rising wind turbine towers

Our protection solutions go beyond components during transportation and storage.

We create and produce fitted top covers for erected tower sections as a climate barrier to the rising wind turbine towers.

Our top covers will protect the towers and keep the electrical equipment inside safe for its purpose. We ensure that the covers are made to the individual aspects of the tower and to fit all sections.

Wind turbine HUB

We protect all components for wind turbines, and the protection of HUBs is no exception. Our in-house R&D team creates the protective covers in cooperation with our customers to ensure a perfectly fitted protection cover.

Our experience ensures you get suitable material and cover for every unique product journey.

Unique engineering for special needs

Our in-house engineering department is talented in creative thinking.

This, combined with our talented product developers’ and streamlined production facilities across the world, guarantees a protection solution that fulfills all needs, and of course, is delivered on time.

A very PVC Free material

A very PVC Free material

FreeTarp represents our latest advancement in more environmentally friendly tarps, being PVC Free, Phthalate Free, BPA Free, Antimony Free, Lead & Heavy Metal Free.

By choosing FreeTarp, you get a cover solution with reduced environmental impact.